A rectangular cold box consists of a steel frame with panels of sheet metal. The cold box containing all cold equipment is designed considering strength and thermal aspects.

Co Cold Box Syngas Separation And Purification Air Liquide

We have delivered over 350 units worldwide to natural gas industrial gas and petrochemical processing plants.

. The housing includes a breakaway barrier between the main cold box and the external housing to. Mineral wool was used for insulation prior to the late 1940s. Cryogenic design otherwise known as the ability to fabricate dewars containers tanks cryostats and transfer systems to exact customer specifications has been one of the many strong points of this organization.

Afterwards the various elements can be separated using fractional distillation. Component layout inside the chamber is decided to maintain a temperature gradient through the length of the chamber. The FRIB cryogenic engineering group designed and built the sub-atmospheric cold box which supports the 2 K 31 mbar operation of the FRIB accelerator cryo-modules.

Capacity upto 2 kW at 45 K. The cold box in an air separation unit is a highly engineered large rectangular box enclosing the major cryogenic equipment. The cooling of air is allowed by passing the cold.

Design Except for CCs. This process is based on. Many industrial applications use gases such as oxygen nitrogen and argon.

Astronomy receivers are generally operated at cryogenic temperatures. Cryogenic Cold Box Cryogenic Cold Box is part of cryogenic liquification or refrigeration plant. Cryogenic Valve Model C2041-C21-1194.

This regime occurs for gas densities where the mean free path is less than the wall spacing. Cold Box is a insulated carbon steel enclosure with flange terminationsIts best described as a process module incorporating all the following Supports and housesheat exchangers piping other related cryogenic equipment that hold a gas or liquid at a very low temperatureThe heart. Vessel Post filter Cold box Cold box Heat exchangers Expansion turbines Inlet and out let manifolds A column consisting of aluminium rays.

As Bobby rightly said you need to develop a technical specification and the vendors will design the same for you. Knudsen July 2019 CEC Slide 7 Sub-Atmospheric Cold Box. The cold box wall is made up of steel panels that are welded onto the cold box frame.

4 Flow chart of Air separation unit The compressed air is passed through heat exchanger which. Reduces the temperatures of the air around -140C. Ad Browse discover thousands of brands.

The cryogenic equipment is enclosed in an insulated enclosure termed a cold box. The custom cryogenic fabrication process begins by identifying the exact. Some suppliers use a round silo design in which the equipment is primarily supported from the cold box foundation.

So the chamber can be thought of two chambers. These gases are obtained using cryogenic gas separation technology whereby air is condensed and converted into a liquid. It also provides structural support for the equipment.

One 4 K part and another 20 K part. Plant comes complete with coldbox turbine duct and control system based on customer. Fives is a pioneer with more than 60 years of industry-leading expertise in cold box design production installation and maintenance.

35 Cryogenic Cryogenic processes operate at temperatures below approximately -90C -130F from EIGA Doc 146 10. A CO 2 cryogenic separation process is proposed and designed for the new liquefied natural gas LNG purification cold box. Hi Cold box is nothing but a Brazed Aluminium Heat Plate Fin Heat Exchanger.

For a detailed explanation of perlite expansion see info sheet. To a cryogenic system At pressures near 1 Atm the heat transfer is by natural convection At lower pressure convection is reduced but gas conduction still can transfer considerable heat k T. So-called air separation plants are characterised by an extremely low temperature of as low as.

Design and analytic services for cryogenic heat exchangers pre-launch LOX and H2 densifiers MLI systems H2 liquefiers storage and transport dewars mixed gas coolers and LNG systems. We deliver a range of coldboxes in sizes of up to 5 m by 7 m and up to 40 m long. This disclosure discusses providing safer and more accessible insulating cold boxes for cryogenic equipment.

Thus the cryogenic system is a crucial element governing a receivers performance. Cylindrical cans with insulation are also used in certain applications. In order to reach cryogenic temperatures a vacuum chamber Dewar containing the receiver is evacuated to a very high vacuum and a closed-cycle refrigerator is used to remove the heat.

A CO2 cryogenic separation process is proposed and designed for the new liquefied natural gas LNG purification cold box. Cryonorm can also offer standardized Nitrogen plant for cryogenic purity GAN 1000 Nm 3 hr production and up to 10 LIN production. Energy business line is specialized in the design manufacture installation and maintenance of brazed heat exchangers cold boxes cores-in-drums and.

Optimal cryogenic cold box design thanks to decades of experience. Our engineers can assist in detailed engineering for instance converting US based design to European standards. This process is based on the liquefaction process using brazed plate heat exchanger BPHE and two separators are embedded between the liquefaction and subcooling heat exchangers to remove frozen CO 2The separator adopts.

5 Cold Box Cuff Globe Valve Pneumatic Actuated Operation. Cryogenic processes require insulation to reduce heat transfer from the surrounding. The centrifugal cryogenic cold compressors designed with room temperature motors.

A cold box of the current invention includes a housing partially extending out of the cold box jacket wherein equipment that may need to be accessed can be located. The physical character of expanded perlite lends itself to a variety of special purposes including use in insulating cryogenic and low temperature storage tanks in shipping containers cold boxes test chambers and in food processing. Read customer reviews find best sellers.

Cryogenic containers that fit your exact specifications. However the term cold box is sometimes used to refer to all enclosures regardless of cross section shape. Refer API 668 or ALPEMA standard for the same.

Packaged units also known as coldboxes are utilised in a wide range of applications for the treatment of cryogenic fluids and gases including air separation plants gas separation and liquefaction plants chemical and petrochemical plants.

Fives Energy Cryogenics Cold Boxes Fives Group

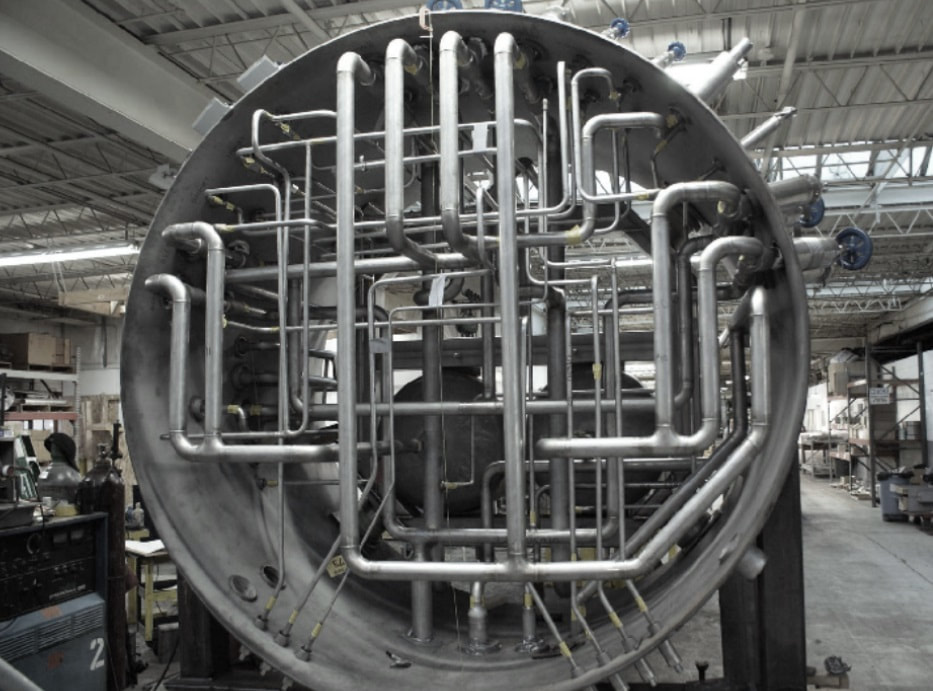

Custom Cryogenic Distribution Boxes And Cold Boxes Meyer Tool Mfg

Cold Box Sumitomo Precision Products Co Ltd

Cold Box Sumitomo Precision Products Co Ltd

Cold Box Installation Operation And Maintenance Chart Energy

Custom Cryogenic Distribution Boxes And Cold Boxes Meyer Tool Mfg

0 comments

Post a Comment